Features & Benefits

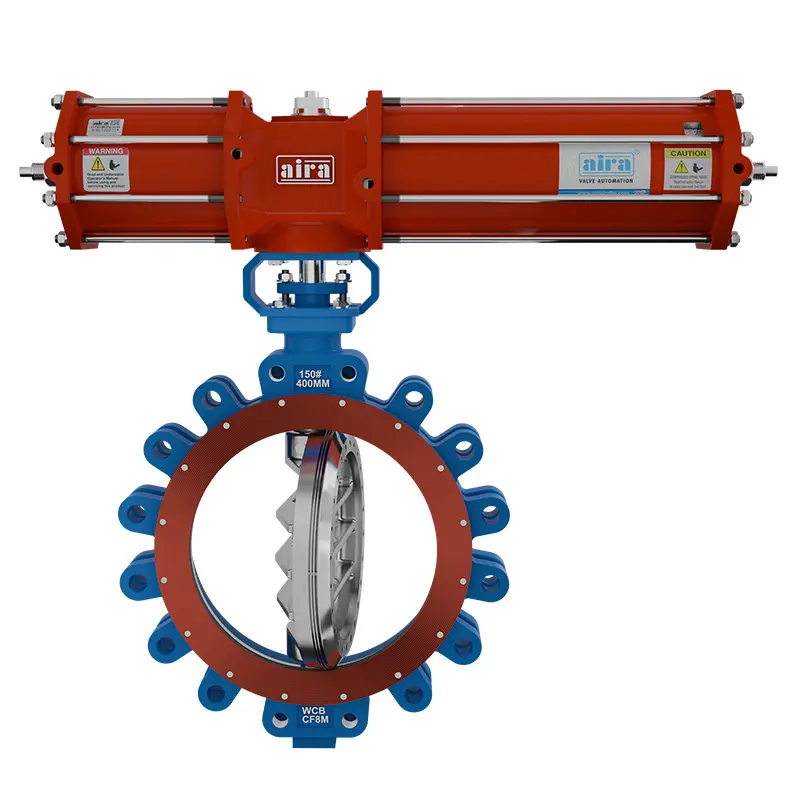

The aira Triple Offset Lug Type Butterfly Valve is engineered for high performance and reliability in demanding applications.

1 – Triple Offset Design: Provides excellent sealing and minimizes friction, ensuring a tight shut-off and reducing torque requirements.

2 – Lug Style: Designed with integrated lugs for easy mounting and dismounting between flanges, facilitating straightforward installation and maintenance.

3 – Robust Construction: Built from high-quality materials to endure extreme conditions and high pressures.

4 – Enhanced Sealing: Advanced sealing technology minimizes leakage and enhances operational reliability.

5 – Versatile Use: Ideal for various industrial applications, including water treatment, chemical processing, and power generation.

For your ease and safety, aira euro has manufactured a Pneumatic Rotary Actuator Operated Triple Offset Lug Type Butterfly Valve with Fire safe design to prevent accidents in your work area.

Materials:

We use ASTM A 216 Gr. WCB A 351 Gr. CF8 / CF8M / CF3M casting material for Body, AISI 410 / 304 / 316 for Shaft, ASTM A 351 Gr. CF8 / CF8M / CF3M for Disc, and Metal to Metal / EPDM material for Seat.

Specialty:

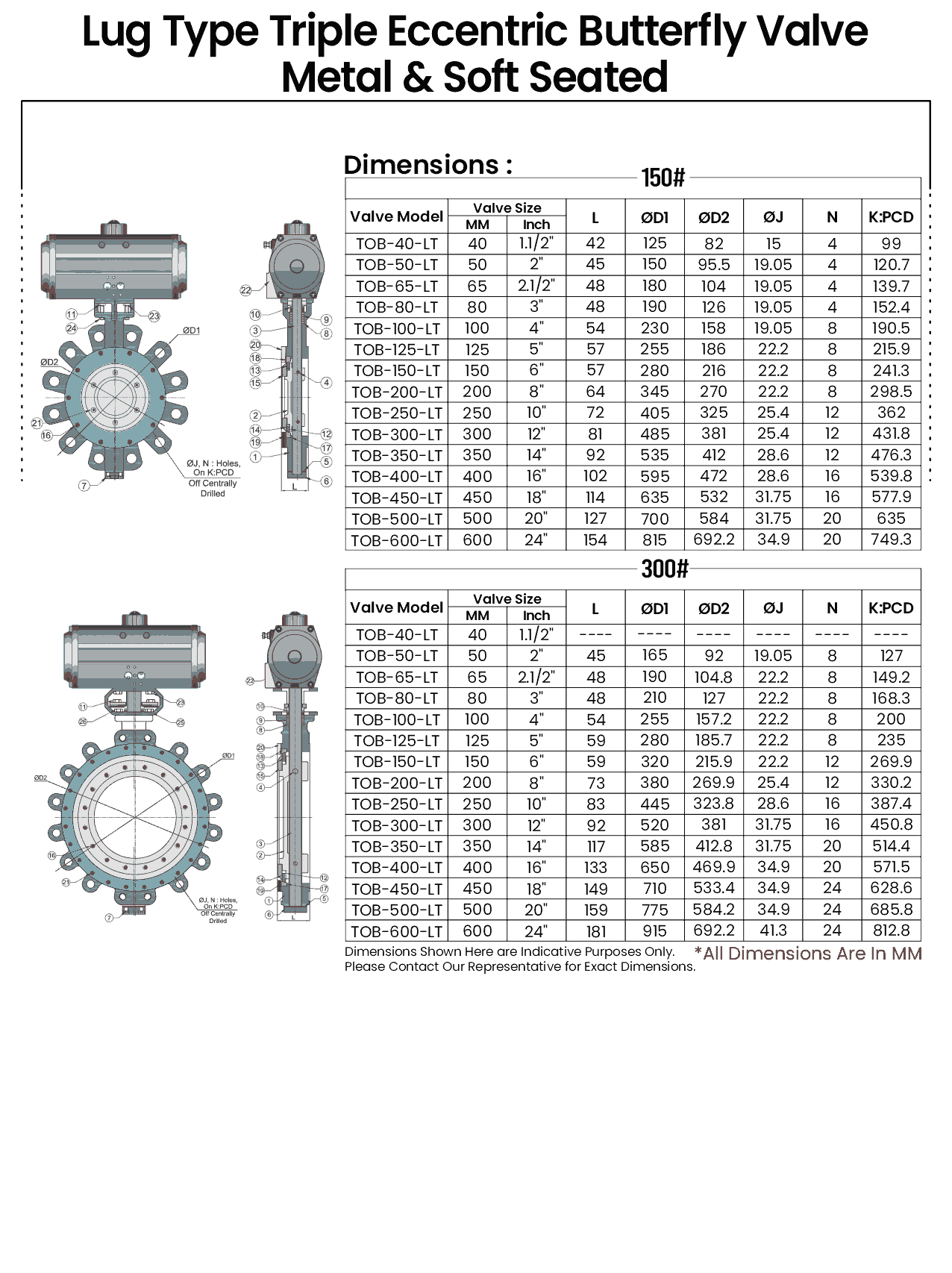

This valve is available in 1.½” to 48” in size can easily sustain pressure up to 10 BAR and temperature up to 120°C in EPDM material and 300°C in Metal to Metal. It comes up with VI leakages as per ANSI B 16, 16.104, and Lug type End connections.

Where to use:

These valves are useful to control the flow of Oil/ Gas/ Steam/ Water/ Air/ Chemical & Vacuum. So it is very useful in Oil refineries, Petro- Chemical Plants, Gas Plants, etc.