”AIRA” Introducing our premium butterfly valve. This Valve boasts a unique design ensuring no deposit on the disc, guaranteeing optimal performance and longevity. Equipped with a PTFE seat, it facilitates a seamless flow, maintaining the integrity of your processes. The specially tailored design of this butterfly valve is dedicated to handling powder application with utmost efficiency. Invest in reliability, invest in performance – choose our butterfly valve for a seamless and efficiency. Solution in your pharmaceutical and chemical operations.

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | API 609 Category A / BS – EN – 593 |

| Valve Face To Face Dimension | API 609 Category A |

| Inspection & Testing | API 598 / BS EN 12266 PART – 1 |

| Leakage Class | Class VI |

| End Connection | Lug Type |

| Valve Rating | Flanged 150# |

| Spark Test | 15 Kv DC to 40 Kv DC |

| Body Type | Lug Type |

| Fugitive Emissions | Yes |

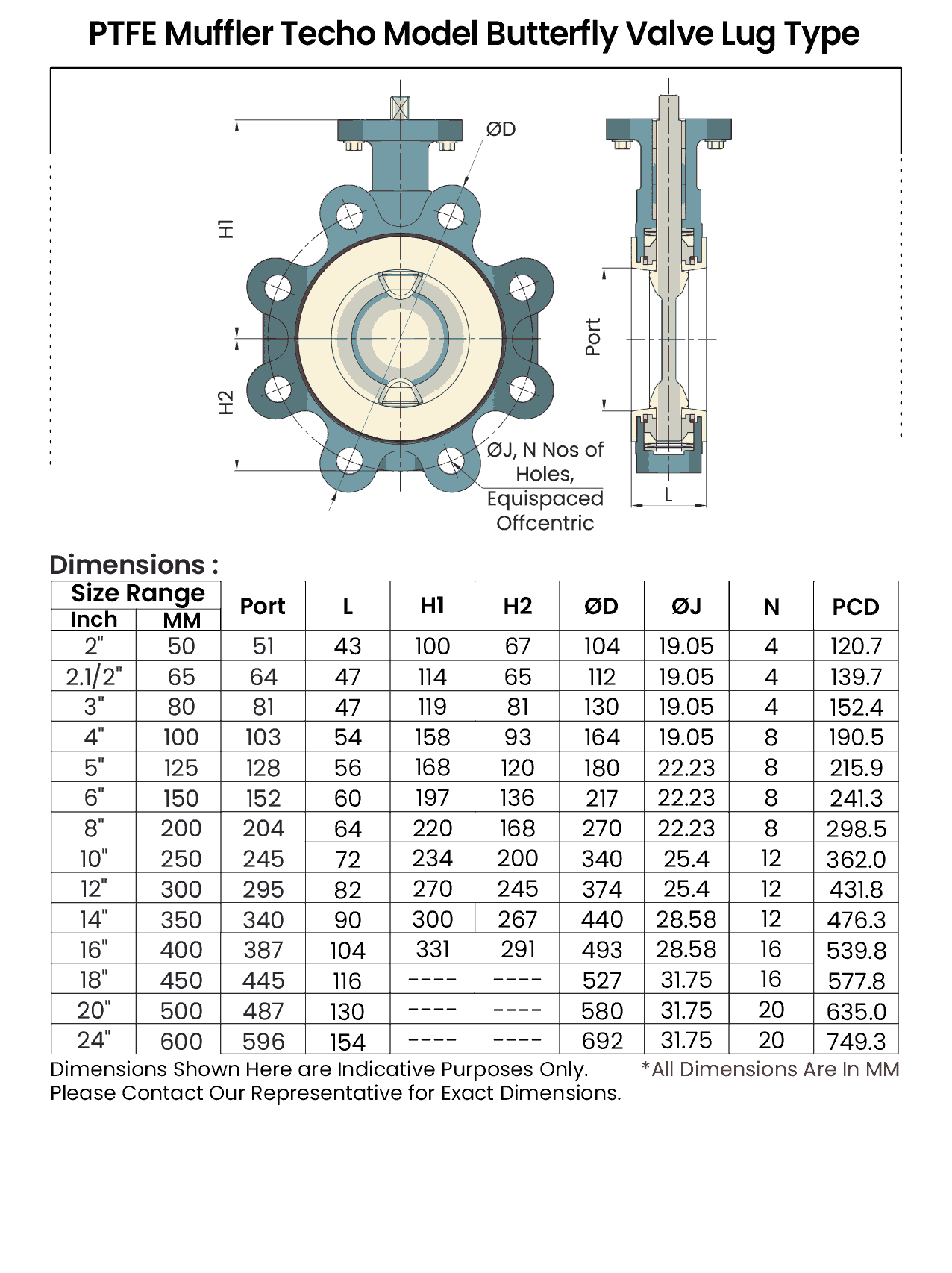

| Size Range | 2” To 24” (50MM To 600MM) |

| Temperature Range | -50°C TO 300°C For Soft Seated Valves. Contact Works For Special Requirement |

| Pressure Class | PN-6 |

| Body Material | CAST IRON (CI), DUCTILE IRON (DI), S.G IRON (SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Disc Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Sleeve Material | PTFE, RPTFE, CFT, GFT, TFM-1600, AIRA-250, NYLON, DEVLON, PEEK, FEP |

| Flanged Drilling | ISO 5211 II |

| Shut Off Rating | VI Class |

| Stem Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |