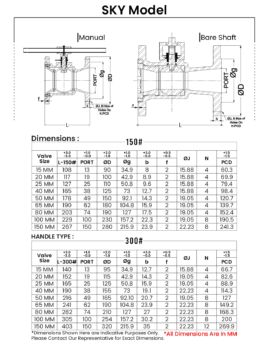

“aira” Offers Automation And Manually Operated Flanged Ball Valves Feature A Compact, One Piece Body Design With Flanged Insert. The One Piece Body Suppliers Maximum Structural Strength While Minimizing The Number Of Potential Leak Paths. A Floating Ball Design Offers Low Torque And Increase Valve Cycle Life. These Rugged, Economical, End-entry Flanged Ball Valves Are The Ideal Solutions From The “aira” Product Line For Industrial Applications.

| Specification | Details |

|---|---|

| Design & Manufacturer | BS EN ISO 17292 / ASME B 16.34 |

| Valve Face To Face Dimension | ASME B 16.10 – 150# & 300# |

| Inspection & Testing | API 598 / ISO-5208 / BS EN 12266-1 |

| Temperature Range | PTFE: Upto 180°C / PEEK: 250°C , RPTFE: Upto 220°C / AIRA250 |

| Media | Air / Water / Oil & Gas |

| Ball Material | CF8, CF8M, WCB+ ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Stem Material | AISI 410, SS 304, SS 316, SS 304L, SS 316L, Duplex 2205, Duplex 2507, Monel |

| Flange Drilling | ASME B 16.5 Class 150#/ DIN/ JIS |

| Leakage Class | ISO 5208 Class VI / B16.104 , ANSI FCI 70-2 (BUBBLE TIGHT SHUTOFF) |

| End Connection | ASME B 16.5 CLASS 150/300 FOR FLANGE END |

| Size Range | 1/2″ to 6″ Flanged 150# & 300# |

| Pressure Class | 150# , 300# |

| Body Material | CAST IRON (CI), DUCTILE IRON (DI), S.G IRON (SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Ball Type | Hollow & Solid |

| Seat Material | PTFE, RPTFE, CFT, GFT, MODIFIED PTFE, AIRA-250, NYLON, DEVLON, PEEK |