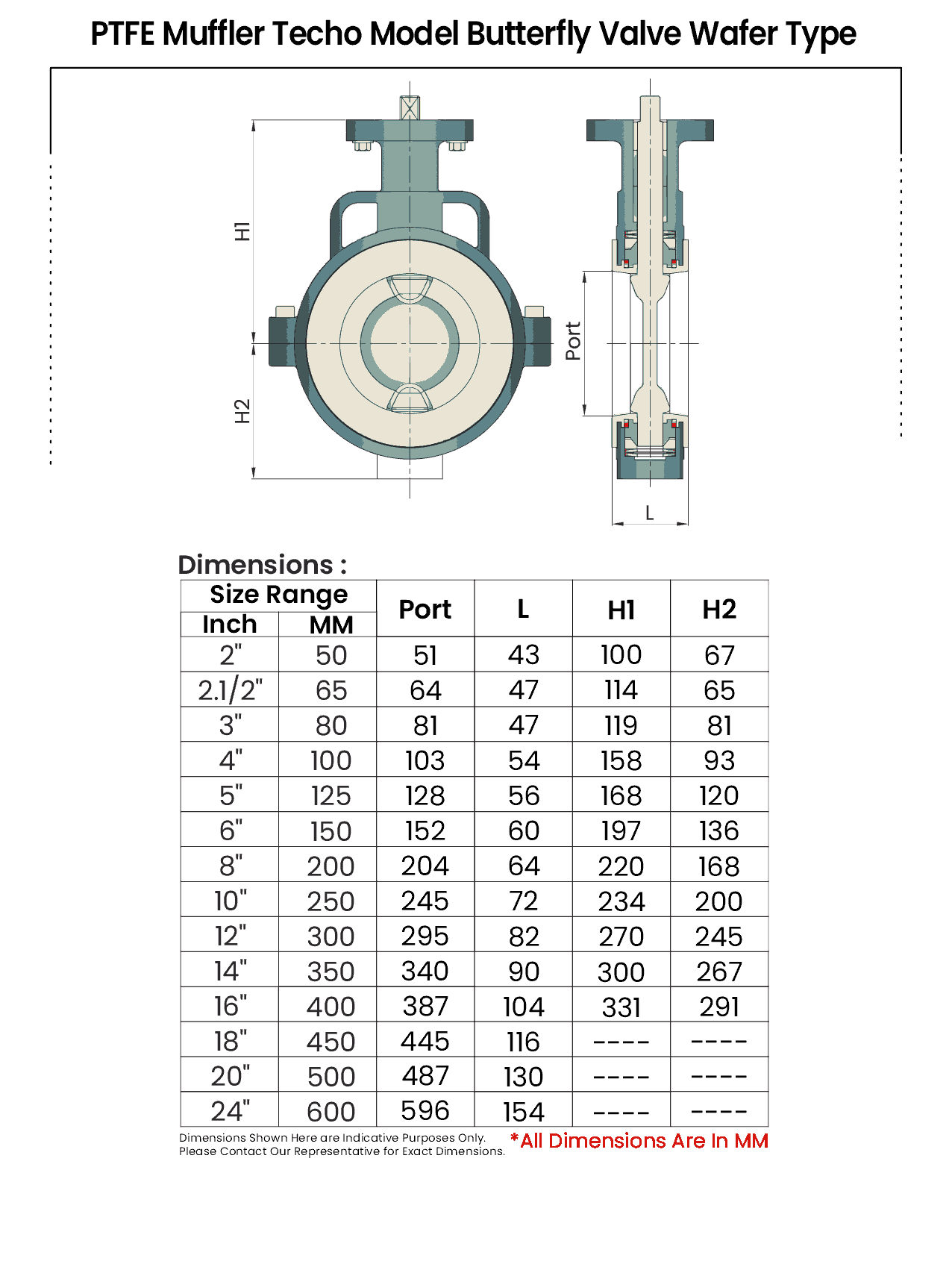

Aira Euro Automation Offer Pneumatic Actuator Operated Techo Model S.G. Iron / CF8 / CF8M Body & CF8 / CF8M Disc 2 Piece Body Teflon Sleeve Butterfly Valve with Mirror Finish Disc PN 10 (Replaceable Muffler)

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | API 609 Category A / BS- EN- 593 |

| Valve Face To Face Dimension | API 609 Category A |

| Inspection & Testing | API 598 / BS EN 12266 PART – 1 |

| Leakage Class | Class VI |

| End Connection | Wafer Type |

| Valve Rating | Flanged 150# |

| Spark Test | 15 KV DC to 40 KV DC |

| Body Type | Wafer Type |

| Stem Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Size Range | 2” to 24” (50MM To 600MM) |

| Temperature Range | -50°C To 300°C For Soft Seated Valves. Contact Works For Special Requirement |

| Pressure Class | PN-6 |

| Body Material | CAST IRON (CI), DUCTILE IRON (DI), S.G IRON (SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Disc Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Sleeve Material | PTFE, RPTFE, CFT, GFT, TFM-1600, AIRA-250, NYLON, DEVLON, PEEK |

| Flanged Drilling | ISO 5211 II |

| Fugitive Emissions | Yes |

| Shut Off Rating | VI Class |