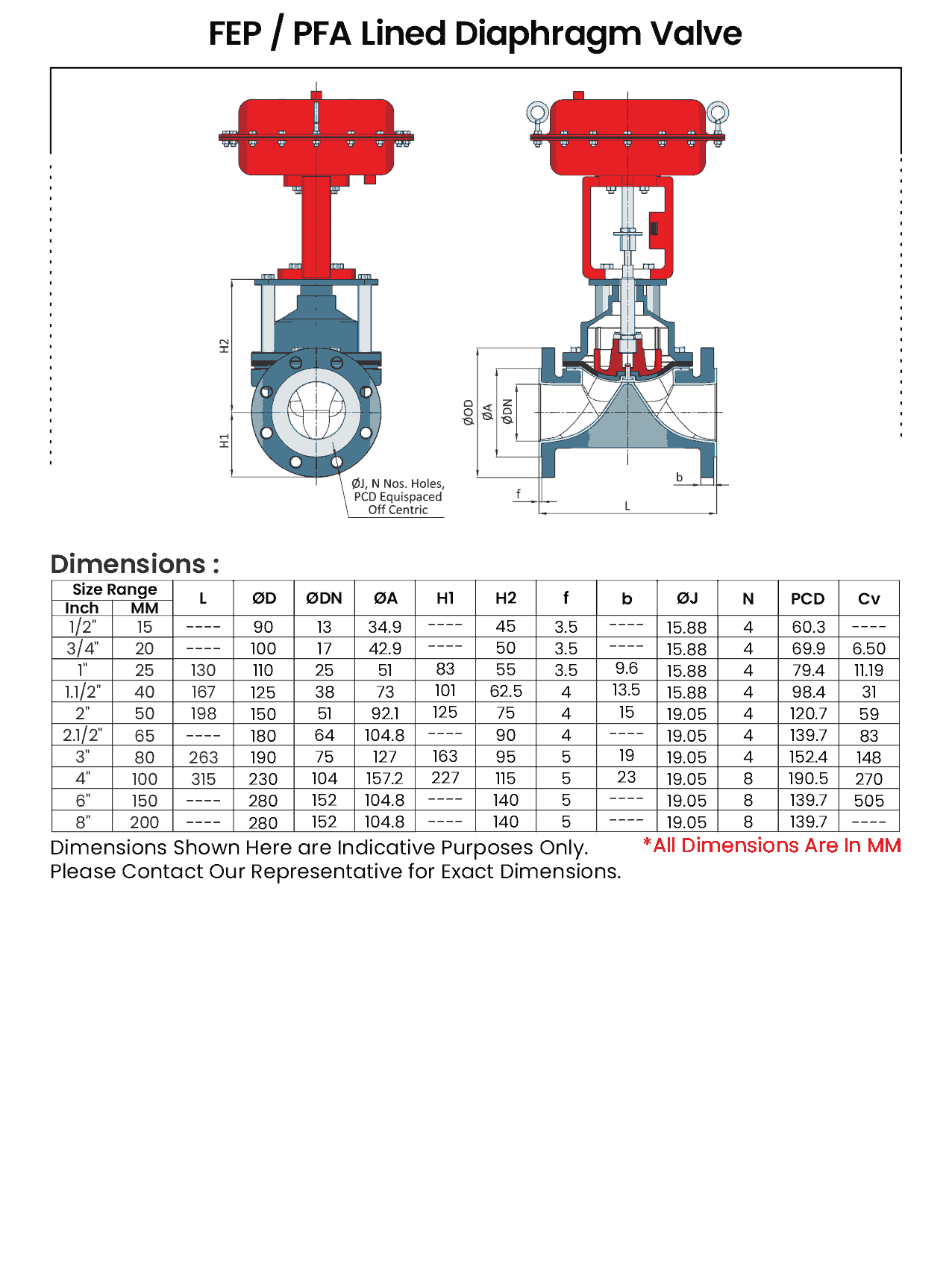

aira” Offers FEP/PFA Lined Diaphragm Valves are generally used for pressure, temperature, flow & level control of extremely Corrosive, Hazardous, Pure Liquid, Vapours and Gas Media in the Chemical, Pharmaceutical and Other industrial applications. This lining is done in – house.

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | API 600 / BS 1873 |

| Valve Face To Face Dimension | DIN 3202 |

| Inspection & Testing | API 598 / BS EN 12266 PART – I |

| Leakage Class | Class VI |

| End Connection | Flanged 150# |

| Valve Rating | Flanged 150# |

| Spark Test | 15 Kv DC to 40 Kv DC |

| Size Range | 1/2” To 8” (15MM To 200MM) |

| Temperature Range | -50°C To 300°C For Soft Seated Valves. Contact Works For Special Requirement |

| Pressure Class | PN 6 |

| Media | Chemical |

| Body Material | CAST IRON (CI), DUCTILE IRON (DI), S.G IRON (SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Bonnet Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Design Standard | BSEN ISO 17292, ASME B 16.34 |

| Flange Drilling | ASME B 16.5 CLASS 150# |

| Certification | Design CE Approved, SIL3 Approved, IBR Approved |

| Face To Face | ASME B 16.10 |

| Body Type | Flanged |

| Shutoff Rating | VI Class |

| Fugitive Emissions | Yes |

| Stem Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Disc Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |