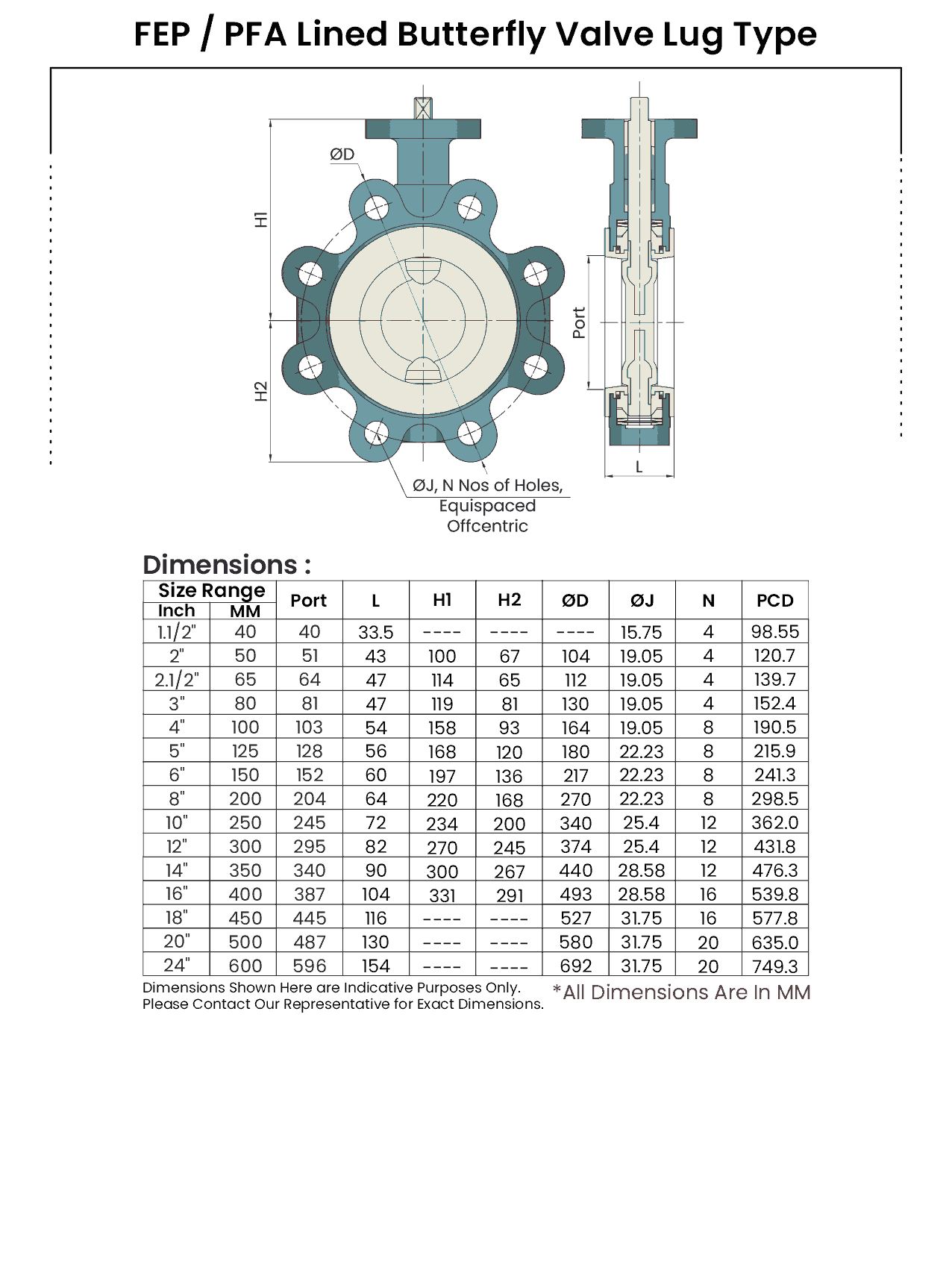

”aira” Offers FEP / PFA Lined valves are well suited for consistent performance requirements in highly corrosive application Chlorine, Benzene, Sulphuric acid, Nitric acid, Phosphoric acid , Hydrochloric acid & Sea Water, Virgin grade resin & thick fluoropolymer linings provide for superior resistance to corrosive chemical effects, Absorption & Swelling.

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | API 609 Category A / BS – EN – 593 |

| Valve Face To Face Dimension | API 609 Category A |

| Inspection & Testing | API 598 / BS EN 12266 PART – 1 |

| Leakage Class | Class VI |

| End Connection | Lug Type |

| Valve Rating | Flanged 150# |

| Spark Test | 15 Kv DC to 40 Kv DC |

| Body Type | Lug Type |

| Fugitive Emissions | Yes |

| Size Range | 1.1/2” To 24” (50MM To 600MM) |

| Temperature Range | -50°C To 300°C For Soft Seated Valves. Contact Works For Special Requirement |

| Pressure Class | PN-6 |

| Body Material | CAST IRON (CI), DUCTILE IRON (DI), S.G IRON (SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Disc Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Sleeve Material | PTFE, RPTFE, CFT, GFT, TFM-1600, AIRA-250, NYLON, DEVLON, PEEK, FEP |

| Flanged Drilling | ISO 5211 II |

| Shutoff Rating | VI Class |

| Stem Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |