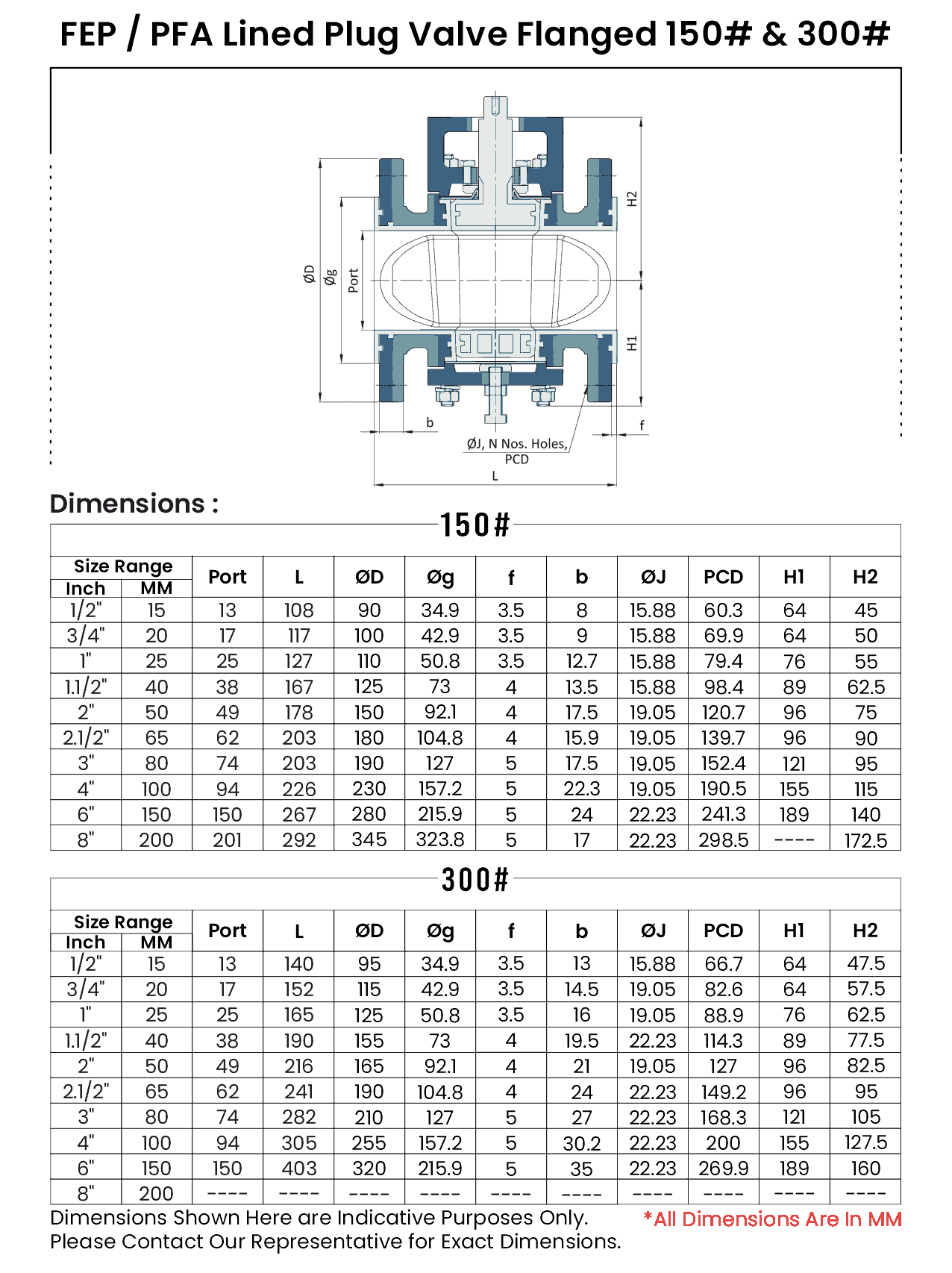

”aira” offers/PFA Lined Plug Valve Fully – lined, quarter turn non lubricated plug valve ideally suited for corrosive application. Locking of Liner to body and molding technique permit use on many chemical services with higher pressure and vacuums without fear of liner collapse, shrinkage, stress cracking and blowout. Excellent sealing capability.

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | BSEN ISO 17292, ASME B 16.34 |

| Valve Face To Face Dimension | As Per BS 16.10 |

| Inspection & Testing | BS EN 12266 – 1 / ISO – 5208 |

| Leakage Class | Class VI As Per ISO – 5208 |

| End Connection | Flanged 150# / 300# |

| Valve Rating | Flanged 150# |

| Spark Test | 15 Kv DC to 40 Kv DC |

| Size Range | 1/2” To 8” (15MM to 200MM) |

| Temperature Range | -50°C To 300°C For Soft Seated Valves. Contact Works For Special Requirement |

| Pressure Class | PN 6/10 |

| Media | Chemical |

| Body Material | CAST IRON (CI), DUCTILE IRON (DI), S.G IRON (SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Plug Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Design Standard | BSEN ISO 17292, ASME B 16.34 |

| Flange Drilling | ASME B 16.5 Class 150# |

| Certification | Design CE Approved, SIL3 Approved, IBR Approved |

| Body Type | Flanged 150#, 300# |

| Fugitive Emissions | Yes |

| Shutoff Rating | VI Class |

| Stem Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Disc Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |