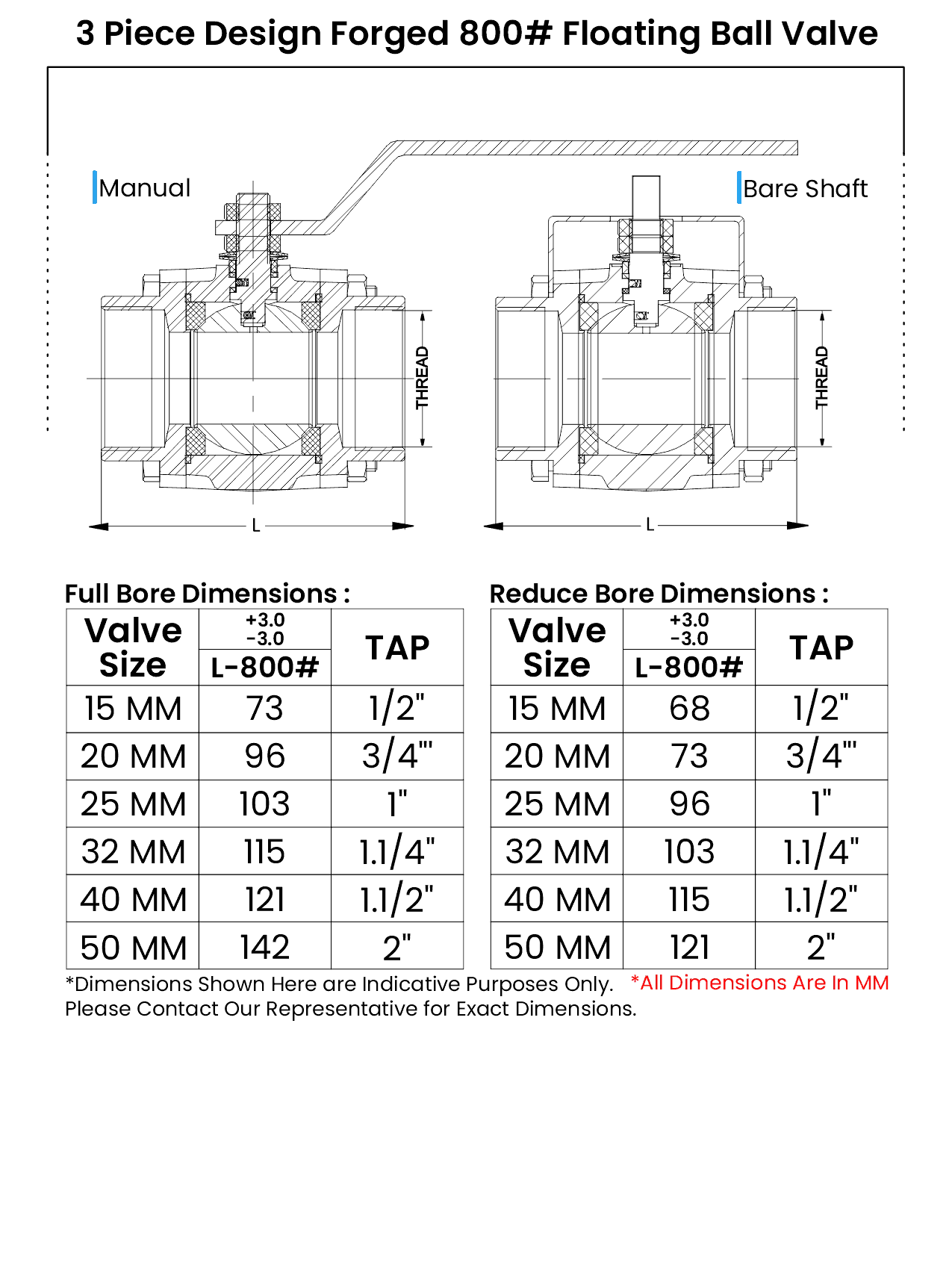

“Aira” Offers Forged Ball valves an Enviro Friendly Flow-control Solution For Steam Lines. The Valve Offers Significant Saving Of Process Steam Compared To Multi-turn Valve With Rising Stem. It Is Designed To Handle 103 Bar Pressure At 38°C And 5 Bar Pressure At 270°C. The Valve Achieves Bubble-Tight Isolation In Steam Lines Leveraging The Time-tested “aira” Ball Valve Design And Special Filled PTFE Seats. The Quarter-Turn Valve Is Suited For Quick Closing Services And Can Be Easily Automated To Meet Customer Requirements.

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | ASME B16.34 / BS EN ISO 17292 |

| Valve Face To Face Dimension | As Per Manufacturer Std. |

| Inspection & Testing | API 598/ ISO-5208/ BS EN 12266-1 |

| Size Range | 1/2″ To 2″ SCREWED/ SOCKET WELD |

| Temperature Range | -25°C to 180°C For Soft Seated Valves. Contact Works For Special Requirement -195°C, -45°C, +300°C (On Request) |

| Pressure Class | 800# |

| Certification | POD |

| Seat Material | CFT, GFT, MODIFIED PTFE, AIRA-250, NYLON, DEVLON, PEEK |

| Leakage Class | ISO 5208 Class VI/ FC1-70-2/ ASME B16.16.104 |

| End Connection | ISO 7-1 For Screwed BSPT/ ASME B1.20.1 For Screwed NPT/ ASME B16.11 for Socket Weld |

| Media | Air/ Water/ Oil & Gas |

| Body Material | A105, A106, AF 16.11 |

| Ball Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Ball Type | Solid |

| Stem Material | AISI 410, AISI 304, AISI 316, AISI 304L, AISI 316L, DUPLEX 2205, DUPLEX 2507, MONEL |