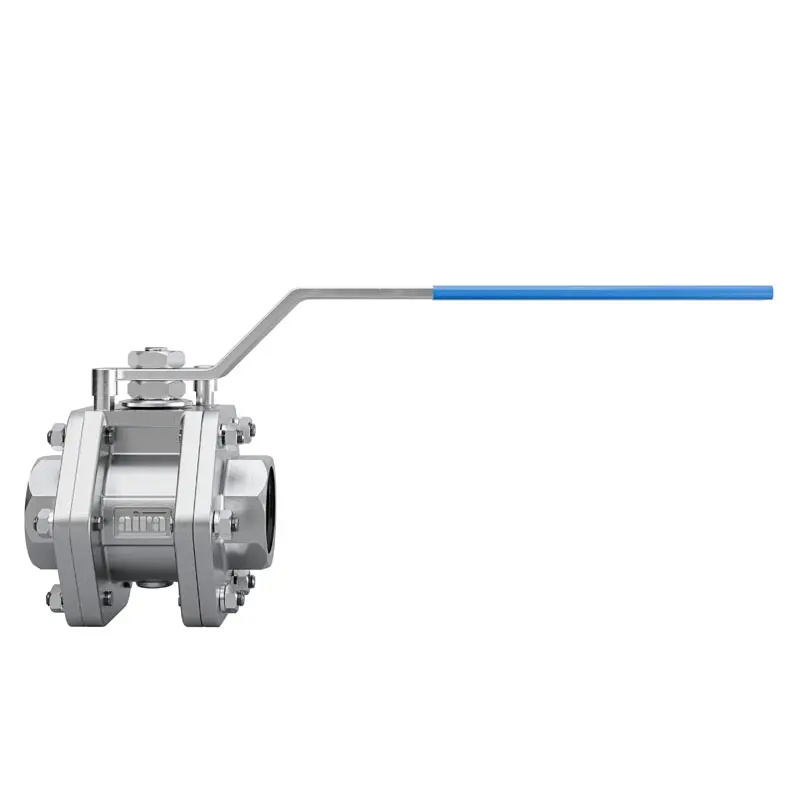

“aira” Offers Automation And Manually Operated Metal Seated Floating Ball Valve Designed For Using In The Several Conditions Such As High Temperature & High Friction Fluids Of Oil & Gas, Petroleum, Petrochemical, Chemical Power Generation, Pulp & Paper, Mining Industry.

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | ASME B 16.34/ BS EN ISO 17292 |

| Valve Face To Face Dimension | ASME B 16.10 |

| Inspection & Testing | API 598/ ISO-5208/ BS EN 12266-1 |

| Leakage Class | ANSI FCI 70-2 Class IV – V |

| End Connection | ISO 7-1 FOR Screwed BSPT/ ASME B 1.20.1 for Screwed BPT/ ASME B 16.5 for Flanged 150# |

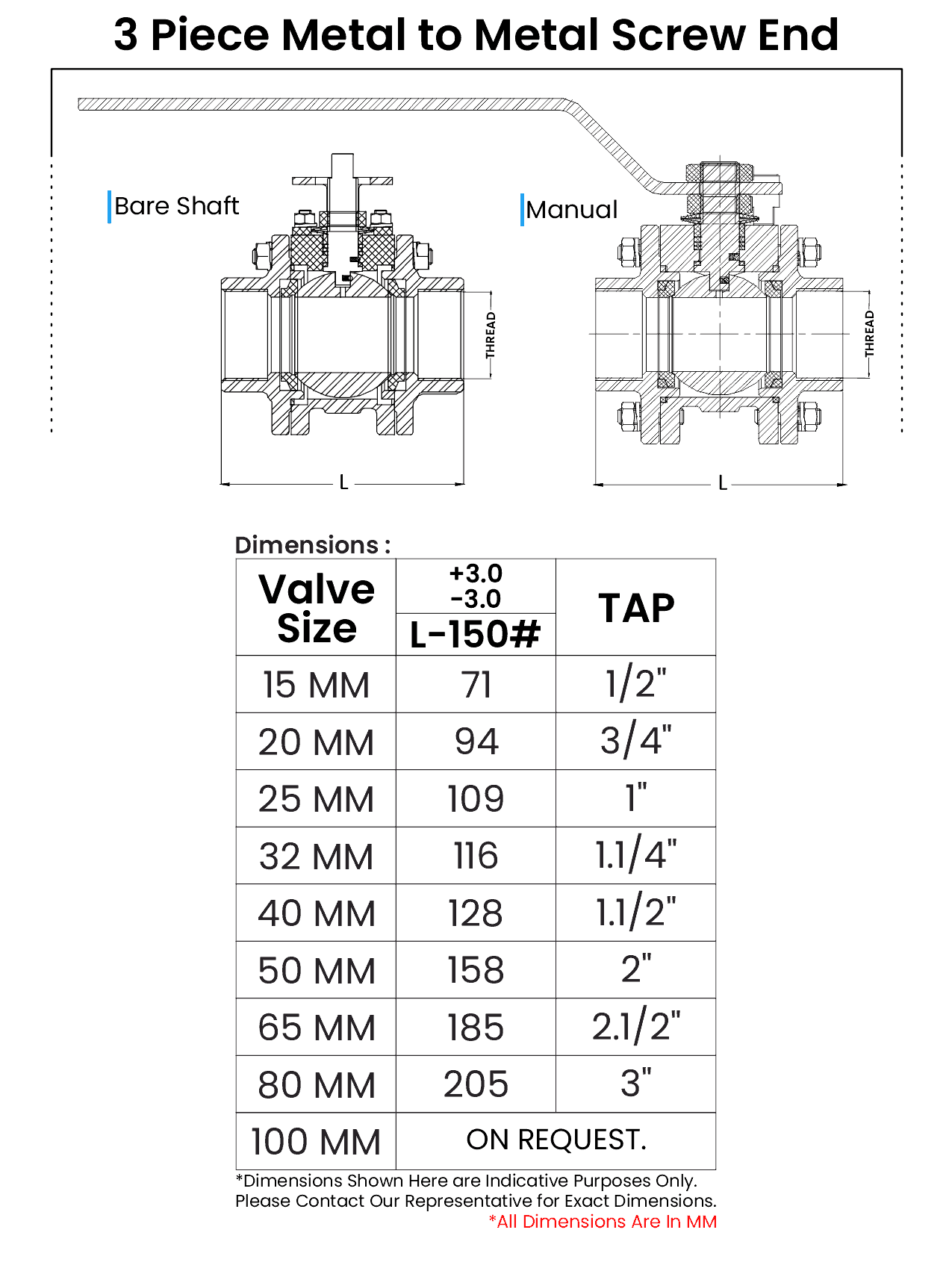

| Size Range | 1/2″ To 4″ Screw End |

| Temperature Range | Up to -50°C To 550°C |

| Pressure Class | 150# |

| Media | Air/ Steam/ Oil & Gas |

| Leakage Class | Class IV To V, VI |

| Body Material | CAST IRON (CI), DUCTILE IRON (DI), S.G IRON (SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Ball Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Ball Type | Hollow & Solid |

| Stem Material | AISI 410, SS 304, SS 316, SS 304L, SS 316L, DUPLEX 2205, DUPLEX 2507, MONEL |

| Seat Material | SS 304, SS 316 |

| Certification | DESIGN CE APPROVED, SIL3 APPROVED, POD |