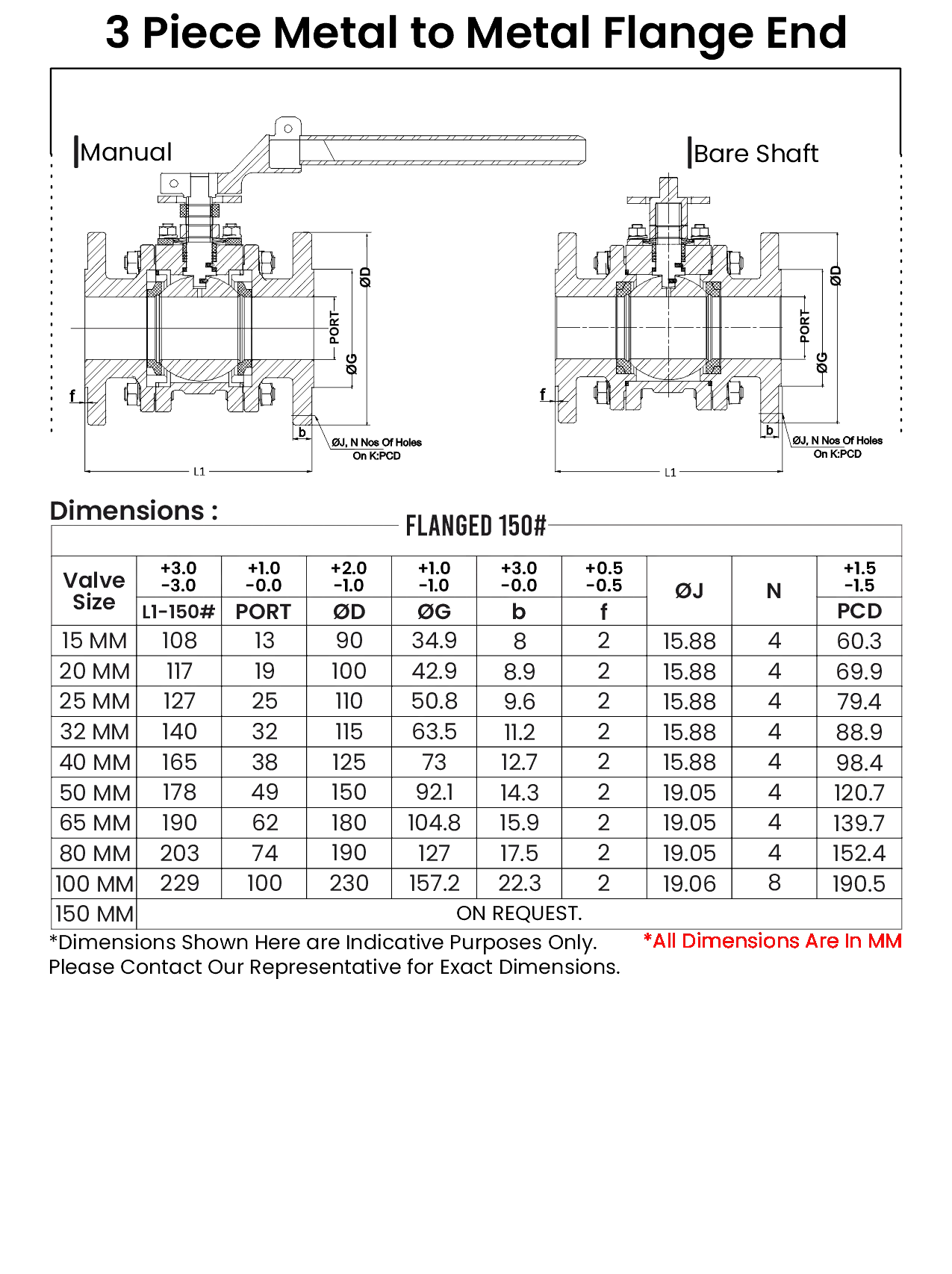

Aira Euro Automation has a huge Ball Valve collection and one of the models is a 3 Piece Fire Safe & Floating Design Ball Valve which is operated by a pneumatic rotary actuator. We use WCB, CF8, CF8M, CF3M casting materials to make the valve body and CF8, CF8M materials for the Ball. The seat connects Metal to Metal and it can sustain Pressure up to 10 BAR. This Ball valve is available in ½” to 4” Inch in size and we can also make it up to 10” inches on request.

Our model can sustain -50°C to 500°C temperature and we are ready to make up to 800°C temperature valves on a customer’s request. It is available in two end connections either screwed Or flanged end connection with 150#, and we can make 300# & 600# class on request.

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | ASME B 16.34/ BS EN ISO 17292 |

| Valve Face To Face Dimension | ASME B 16.10 |

| Inspection & Testing | API 598/ ISO-5208/ BS EN 12266-1 |

| Leakage Class | ANSI FCI 70-2 Class IV – V |

| End Connection | ISO 7-1 for Screwed BSPT/ ASME B 1.20.1 for Screwed BPT/ ASME B 16.5 for Flanged 150# |

| Ball Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Ball Type | Hollow & Solid |

| Certification | DESIGN CE APPROVED, SIL3 APPROVED, POD |

| Size Range | 1/2″ To 6″ Flanged |

| Temperature Range | Upto -50°C To 550°C (750°C Temperature Available On Request) |

| Pressure Class | 150# |

| Media | Air/ Steam/ Oil & Gas |

| Leakage Class | Class IV To V, VI |

| Body Material | CAST IRON, DUCTILE IRON, S.G IRON, WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Stem Material | AISI 410, SS 304, SS 316, SS 304L, SS 316L, DUPLEX 2205, DUPLEX 2507, MONEL |

| Seat Material | SS 304, SS 316 |