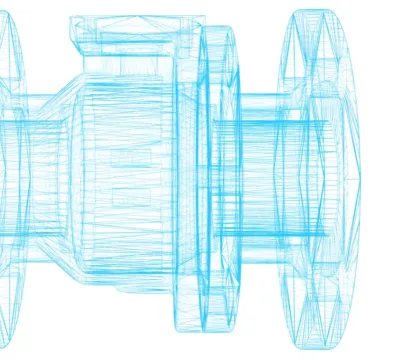

“aira” Plug Valves Are Designed To Offer Superior Performance In Various Industrial Applications. Design Inherent Reduction In Pressure Drop Leads To Higher Efficiency And Better Flow Rates. Long Service Life, Unmatched Sealing Capacity And Ease Of Maintenance Thanks To Ingenious Design Make The aira Plug Valves A Preferred Choice In Severe Service Conditions.

Specification & Standard

| Specification | Details |

|---|---|

| Design & Manufacturer | API 599 / BS 5353 |

| Valve Face To Face Dimension | ASME B 16.10 |

| Inspection & Testing | API 598 / EN 12266-1 |

| Leakage Class | Class VI ISO-5208 |

| End Connection | Flanged 150# & 300# |

| Body Material | CAST IRON (CI), DUCTILE IRON (DI), S.G IRON (SGI), WCB, CF8, CF8M, CF3M, SS 304L, DUPLEX, HAST ALLOY, MONEL |

| Plug Material | CF8, CF8M, WCB + ENP, HAST ALLOY, DUPLEX, MONEL, CF3M |

| Seat Material | PTFE, RPTFE, CFT, GFT, TFM-1600, AIRA-250 |

| Certification | Design CE Approved, SIL3 Approved, IBR Approved, FIRE SAFE Approved, ISO Approved |

| Size Range | 1/2” to 18” |

| Temperature Range | -50°C To 300°C For Soft Seated Valves. Contact Works For Special Requirements |

| Working Pressure | Up to 10 Kg/Cm² |

| Pressure Class | 150#, 300# |

| Media | Air / Water / Oil / Gas / Nitrogen & Chemical |

| Flange Drilling | ASME B 16.5 Class 150# / 300# |

| Face To Face | ASME B 16.10 |